Wire manufacturers and suppliers choose titanium over other metals due to its good properties in strength, corrosion, and weight. Because of its exceptional ability to combine high strength, lightweight, corrosion resistance, biocompatibility, and high-temperature performance, titanium wire is frequently preferred. The wire’s finish options include “annealed and pickled.” Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

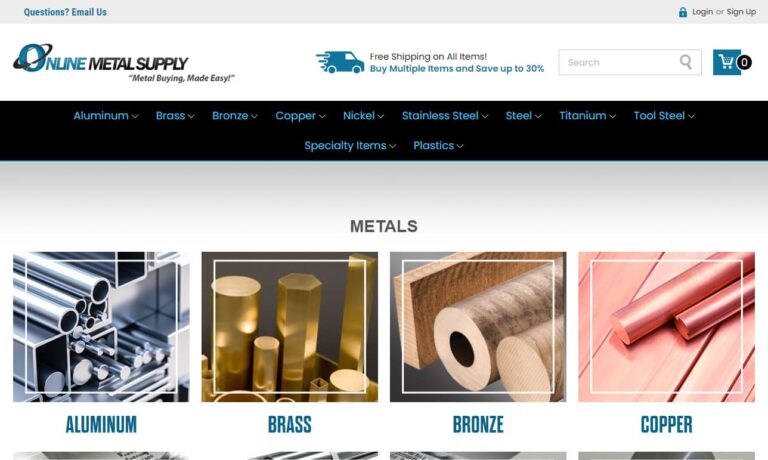

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Titanium Wire Suppliers

Naturally silver-white titanium is a metal with many great qualities. For instance, titanium has a density of 4.54 g/cm2, making it 43% lighter than steel while maintaining steel's mechanical strength. Additionally, titanium is resistant to high temperatures and has a melting point of 1942°K, which is about 500°K higher than steel. Titanium wires are one of the many items manufactured from titanium that have entered our daily lives in recent years because of ongoing research into the metal.

How is Titanium Wire Made?

Three different forms of titanium oxides, namely TiO2, Ti3Al2O5, and Ti4SiC6, are used to create titanium wire, one of the most widely used metals in the world. The material is first melted and heated to a high temperature. Then, it is extruded through a die or wire milling cutter at a temperature of about 3200°Fahrenheit for roughly one second. The result is a pure titanium wire that can withstand temperatures up to 900°Celsius without melting or breaking and has a diameter between 0.008 and 0.010.”

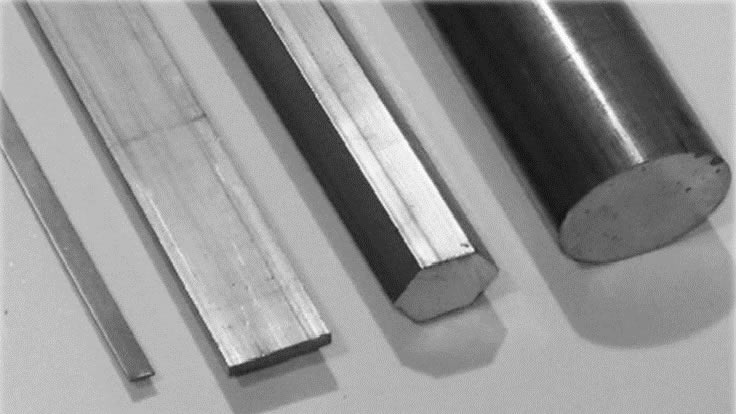

Types of Titanium Wire

Depending on the various characteristics of titanium and titanium alloys, titanium wire can be produced to adhere to a wide range of standards. However, it is typically classified as pure titanium wire, titanium alloy wire, pure titanium eyeglass wire, titanium straight wire, titanium welding wire, medical titanium wire, titanium coil wire, titanium hanging wire, titanium bright wire, and titanium nickel alloy wire. We examine a couple of these types in greater detail below.

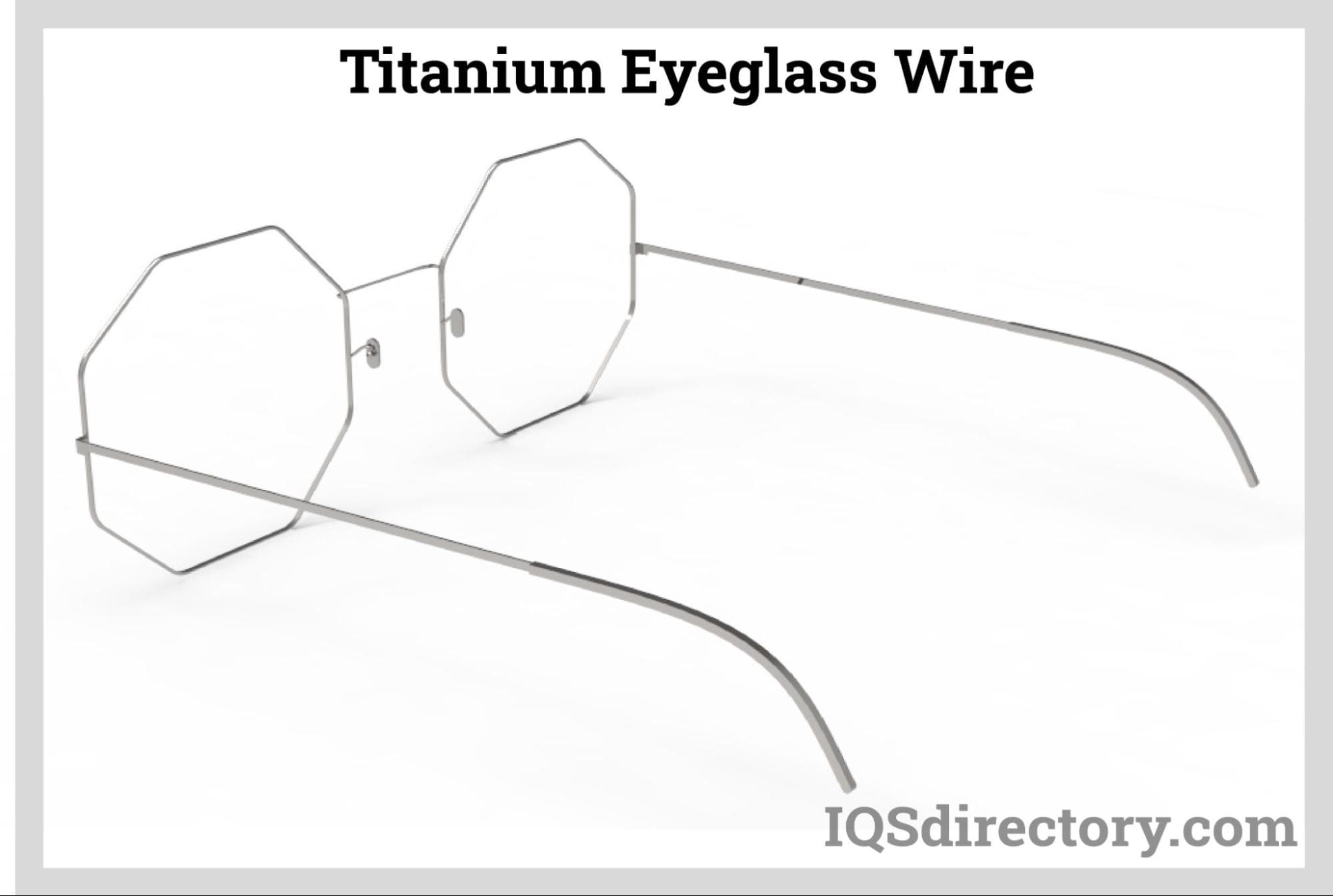

Pure Titanium Eyeglass Wire

For eyeglass frames, titanium is a robust, lightweight metal that works well. In addition, titanium eyeglass wire's appealing silver tone and corrosion resistance make it a desirable material. By alloying titanium with nickel, it can also be turned into a memory metal that can bend and return to its original shape, making it the ideal material for eyeglass frames.

Titanium Coil Wire

Specially shaped wires called titanium coils are wound around a core like a wrapped helix. They are renowned for their high melting and boiling temperatures and are remarkably resilient (given their low density). Although titanium coils can be used in various settings, electrical devices are one of their most frequent applications.

Welded Titanium Wire

Welded wire made of titanium is the perfect product for demanding industrial applications. It is the ideal material for use in welding and fabrication.

Benefits of Titanium Wire

Titanium wire has high durability and strength. Titanium has the highest strength-to-density ratio, making it more suitable for applications like eyeglass frame manufacturing. Titanium has a neutral resistive property to corrosion. Titanium is extremely recyclable, which lowers production costs. Because of its exceptional ductility, elasticity, and low shear strength at high temperatures, titanium wire is strong.

On the other hand, pushing titanium with your hands does not cause the metal to bend. Due to this characteristic, the wire is ideally suited for structural applications. In addition, the wire is perfect for welding because it can be easily machined, polished, and has a surface with a low coefficient of friction.

Applications of Titanium Wire

- It is used frequently in aerospace and biomedical engineering.

- Titanium wire is used for creating parts such as those found in vehicles, boats, and bridges.

- Currently, titanium and titanium alloy wires make up more than 80% of all welding wires used in processes, including welding pipes, welding turbine disks and blades for aircraft jet engines, and welding casings.

- Titanium wire has been widely utilized in chemical, pharmaceutical, papermaking, and other sectors because of its exceptional corrosion resistance. In addition, it can be turned into a mesh for a chemical drug filter, a seawater filter, or a purified water filter.

- Titanium and titanium alloy wires are also used to make fasteners, load-bearing parts, and springs.

- Because titanium and titanium alloy wires work well with the body, they are used to make medical devices like pacemakers, defibrillators and battery components.

- The manufacture of satellite antennas, clothing shoulder pads, women's bras, and eyeglass frames utilize titanium alloy wires with shape-memory properties.

- Wires made of titanium and titanium alloys are used to create a variety of electrodes in the electroplating and water treatment sectors.

Disadvantages of Titanium Wire

- Titanium wire is more expensive than other metal wires.

- Titanium is not suitable for use in extremely high temperatures.

- Many impurities are used in the production of titanium wires using the Kroll process.

Choosing the Correct Titanium Wire Supplier

To make sure you have the most positive outcome when purchasing titanium wire from a titanium wire supplier, it is important to compare at least 4 companies using our list of titanium wire suppliers. Each titanium wire supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each titanium wire company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple titanium wire companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services