The twenty-second element in the periodic table is titanium. It is a silver-colored metal that occurs naturally, often extracted from the earth’s crustal minerals, such as rutile, ilmenite, and sphene. The scientific community learned about it at the end of the 18th century and, by the 20th century, began using titanium in industrial applications. Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Titanium Metal Suppliers

Physical Properties of Titanium

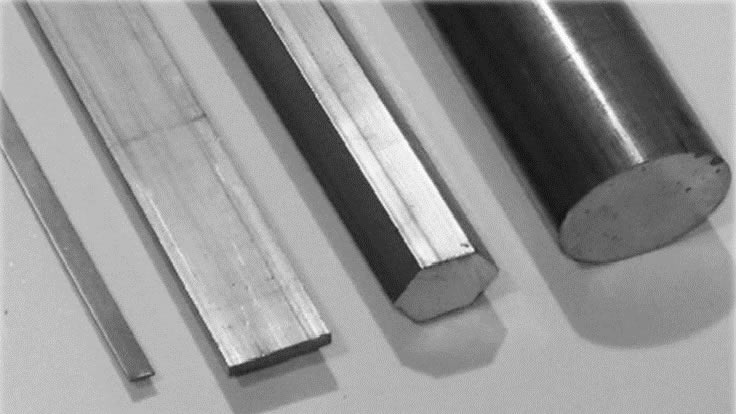

It is thought that titanium metal has higher physical properties. It is believed to be a chemically inert substance. Titanium’s high strength-to-weight ratio makes it ideal for applications requiring lightweight, durable materials, such as dental work. Titanium has a low density of 4.5 g/cm3. Titanium metal has a melting point of 3000°F (1648°C) and a boiling point of 5432°F (3000°C). Titanium is valuable because of its exceptionally high melting and boiling temperatures.

Additionally, it is a malleable metal, especially in a climate devoid of oxygen. Titanium’s shiny grey-white look makes it ideal for coating other metals and for display. Furthermore, pure titanium dioxide has an optical dispersion greater than a diamond and is nearly clear due to its high refractive index. Compared to other metals, titanium has comparatively low electrical and thermal conductivities, but when chilled below its critical temperature of 0.49 K, it develops superconducting qualities. When deuterons bombard titanium in its basic form, it can become very radioactive.

Chemical Features of Titanium

Titanium metals and their alloys instantly oxidize as magnesium and aluminum when exposed to the air. Around 1,200°C, titanium begins to interact with oxygen molecules. Pure oxygen can still react with titanium at 610°C to produce titanium dioxide. When oxygen and water are present, titanium acts as an inert element.

Types of Titanium

Grade 1 Titanium: It is the most malleable, soft, and weldable grade of pure titanium. Grade 1 titanium is used often by the marine, medicinal, and architectural industries. The oxygen (O) % permitted for Grade 1 is the lowest of all the industrially pure grades. Therefore, an increase in oxygen is associated with each grade.

Grade 2 Titanium: Grade 2 titanium is very malleable and moderately strong. It is resistant to corrosion and oxidation. The most typical applications for grade 2 are in desalination, automobile parts, architecture, and aerospace.

Fabrication of Titanium Metals

Titanium is often produced through the Kroll process, which produces titanium metal. The Kroll process includes extraction, purification, creation of sponges, alloy creation, and molding. Most manufacturers specialize in one stage of this procedure. For instance, some manufacturers only make alloys, while others only produce sponges.

First, titanium ores made of rutile or ilmenite are separated. Mining corporations deliver ores to manufacturers, who cook the ores to 800°C using a fluid-bed reactor containing chlorine and carbon. A reaction occurs, producing carbon monoxide as a byproduct and impure titanium tetrachloride as a byproduct. Because titanium dioxide is still not pure after iron removal, the impurities are present in the TiCl4.

The TiCl4 is purified, first by being heated and then placed in a distillation tank. Precipitation and fractional distillation techniques are used to remove the present impurities. These two techniques eliminate all contaminants, particularly silicon, vanadium, magnesium, zirconium, and iron. After purification, manufacturers can create sponges, alloys, or fabricate titanium according to specific needs.

Choosing the Correct Titanium Metal Supplier

To make sure you have the most productive outcome when purchasing titanium metal from a titanium metal supplier, it is important to compare at least 4 companies using our list of titanium metal suppliers. Each titanium metal supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each titanium metal company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple titanium metal companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services