Titanium is a transition metal that is extracted from the element of the same name. Titanium metal grows naturally and abundantly, though not in pure form. Titanium metal is the fourth rarest element on our planet. Metallurgist may find its raw material in the earth’s crust, in water, in rocks and stones, and in minerals. Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Titanium Suppliers

Some of the minerals in which it can be found include rutile (titanium dioxide), ilmenite (titanium dioxide), anatase (titanium dioxide), and brookite (titanium dioxide). On the periodic table, its atomic number is 22 and its chemical element symbol is Ti. It is not to be confused with tin, which is listed on the periodic table as Sn. Its atomic weight is 47.90.

Titanium boasts natural qualities of ductility, heat transference, extreme heat resistance, low density, strength, and high corrosion resistance. In fact, titanium metal is the strongest metal on earth. For being so strong, it is also incredibly lightweight. While it is as strong as steel, it is half its weight. To give you an idea of titanium’s heat resistance, here are some facts: titanium has a melting point of 3,034℉, titanium metal resists temperatures up to 3000℉, and titanium liquid boils at 6000℉.

Titanium Applications

Titanium metal’s qualities lend it to many applications, particularly those related to the aerospace industry, the marine industry, automotive manufacturing, surgery and dentistry, racing sports, jewelry making, and aquariums.

History of Titanium

The first person to discover titanium was William Gregor, both a member of the clergy and an amateur geologist. In 1791 in Cornwall, England, Gregor found titanium oxide in black sand next to a stream. It stood out to him because he found that it was attracted to magnets. Intrigued, he took a closer look, and realized that the sand contained two metal oxides. He knew that one was iron oxide, but he did not recognize the other. As he studied it, he discovered that the unknown oxide, later identified as ilmenite, contained yet another oxide. This was titanium. Gregor called it Manaccanite, after his village and parish, Manaccan.

In 1795, in modern day Slovakia, a Prussian chemist named Martin Heinrich Klaproth discovered titanium dioxide inside a mineral named rutile. Rutile is most commonly found in Switzerland and West Africa. He bestowed upon titanium its current name, in honor of deities from Greek mythology called the Titans. Because Gregor had published his findings, Klaproth was aware of Manaccanite, and he suspected that the element he found in rutile could be the same element found by Gregor. To investigate this, he acquired a sample and tested it. It turned out he was right; both rutile and ilmenite contain titanium dioxide.

Because they couldn’t extract it properly, scientists didn’t really use titanium until about one hundred years after its discovery. The first scientist to do so was Matthew A. Hunter, who worked at the Rensselaer Polytechnic Institute. Basically, he did so by pressurizing and heating titanium tetrachloride (TiCl4) in sodium at temperatures between 700℃ and 800℃. With it, he was able to prepare metallic titanium that was up to 99.9% pure. Today we call his method, introduced in 1910, the Hunter process. About twenty years later in 1932, a metallurgist from Luxembourg, William Justin Kroll, developed another method for extracting titanium. Instead of sodium, he reduced titanium tetrachloride using calcium. In 1940, he replaced calcium with magnesium, making the process work even better. The Kroll process, as we call it now, remains the most popular commercial titanium reduction method.

Engineers began manufacturing titanium metal more heavily in the 1950s and 1960s. The Soviets used it to make submarine equipment and military aircraft, especially high-tech jet planes. They did so because they found that it, unlike other materials, titanium material does not completely dissolve in the air. With titanium aircraft and marine vehicles, they were able for a time to gain an edge over the United States in the Cold War. In response, the United States Defense Department began manufacturing immense amounts of titanium and stockpiling it. They stockpiled so much titanium that the supply did not run out for approximately sixty years.

A little over a decade ago, in 2006, the U.S. Defense Advanced Research Projects Agency (DARPA) awarded $5.7 million to a two-company consortium to develop a new way to make titanium powder. As they have been working on developing this new process, the titanium industry has not slowed down at all. Titanium is incredibly important to a number of advanced industries, such as aerospace and aeronautics, bioengineering, and structural engineering. In addition, as titanium processing improves, we believe that titanium will play an even bigger role in offshore hydrocarbon production, healthcare, water desalination, marine vehicles, chemical processing, gas and oil, architecture, and the automotive industry.

Titanium Production Process

Extraction

Most often, metalworkers extract titanium from where it is found in mineral deposits using either the Kroll method or the Hunter method.

Reduction

After extracting the titanium from the earth, whether they use the Kroll or the Hunter method, metallurgists use magnesium to reduce titanium tetrachloride down to a sponge, which is a highly porous, raw ore.

Shaping

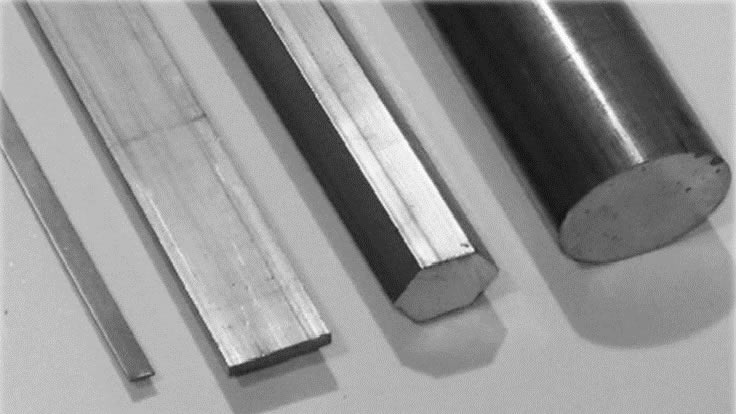

After reducing the titanium, titanium manufacturers melt or press the sponge into blocks to be fabricated. They call these ingots. Alternatively, using other methods, manufacturers may instead process titanium ore into titanium sheet, powder, mesh, granules, foil, or rod.

Product Fabrication

No matter its form, manufacturers can fabricate ore into a variety of parts and shapes, including titanium wire, titanium tubing/titanium tube, and titanium bars. The most common methods of titanium fabrication include welding, flat rolling, and hot or cold forming.

Secondary Processing

After fabrication, manufacturers may put titanium products through any number of secondary processes, such as pickling, blasting, laser cutting, or anodizing.

Pickling is a chemical process by which oxide film is washed from the surface of titanium products.

Blasting uses abrasive particles or mechanical grit to blast from large titanium products like titanium billets or titanium ingots. Mechanical grit leaves behind a fine layer of dust, but it can be removed during pickling.

Laser cutting is a hot cutting process that uses laser technology to slice thin gauge titanium products to close tolerances.

Anodizing is metal treatment; using electricity, a technician covers or coats a metallic surface with a decorative or protective layer of oxide that will not fade like a pigment or die.

Titanium Alloys

To capitalize upon its qualities, manufacturers frequently alloy titanium with other metals, such as steel, stainless steel, iron, or aluminum, to create materials with hybrid qualities.

Titanium alloys are arranged on a grade scale of one to 38 by the American Society for Testing and Materials (ASTM). Titanium grades one through five are non-alloys, while the rest are alloys fused with smaller or larger amounts of elements like zirconium, iron, vanadium, silicon, palladium, aluminum, steel, stainless steel, tin, ruthenium, nickel, niobium, and molybdenum.

They are also organized into three main categories: Alpha, Alpha Beta, and Beta titanium.

Alpha titanium is most often alloyed with aluminum and tin, is ductile, with high notch toughness, good mechanical properties at cryogenic temperatures, and has the highest corrosion resistance. It has low to medium strength and it is non-heat treatable but wieldable. Even though Alpha Beta is stronger, Alpha titanium is still strong enough for use in the manufacturing of chemical processing equipment and airplane parts.

Alpha Beta titanium has medium to high strength and is both heat treatable and wieldable. Alpha Beta is used to fabricate aircrafts, prosthetic devices, and marine hardware.

Beta titanium, the toughest of the group, is fully heat treatable and wieldable. Very dense, it displays a high formability that makes it ideal for fabrication of aircraft parts that need to maintain their shape and structure, even under the most extreme pressure.

Products Produced from Titanium

Titanium is considered a vital metal and has an unending list of applications. This is because titanium metal is particularly durable. As far as engineering applications are concerned, it is corrosion-resistant, extremely strong, and light. It’s 40% lighter than steel yet manifests the same strength as high-strength steel. Carrying such a high degree of simultaneous strength and lightness, it’s no wonder titanium parts are found everywhere.

Biomedical

The biomedical industry relies on titanium bars and wires for catheter and orthopedic device production.

Automotive

In the automotive industry, titanium plates make up parts of rocker arms, connecting rods, valve springs, steering gears, exhaust systems, and drive shafts.

Healthcare

Since pure titanium is so resistant to corrosion, manufacturers also use it to make dental instruments, surgical instruments, and a variety of prosthesis. Titanium rods are, for example, used in scoliosis surgery to support a surgically straightened spine. Titanium is also used to make orthopedic devices like heart stents, joint replacements, bone plate, hip balls, and dental replacements. On top of that, manufacturers can use titanium to create catheters and miscellaneous medical wire and bars.

Aerospace

Manufacturers also use titanium oxide, pure titanium, and titanium alloys in spacecrafts, space stations, missiles, jet engines, and aircrafts.

Titanium has been employed in new alloys and production processes since the invention of the jet engine to fulfill demands for high efficiency, creep resistance, durability, and metallurgical structure.

The best grade titanium metal alloys are obtained by triple melting or, in certain situations, electron beam cold hearth melting. These alloys are employed in engines and airframes in the aircraft industry.

Military

Titanium is extensively used in military equipment due to its exceptional strength, lightweight nature, and corrosion resistance. It is utilized in applications such as aircraft frames, armor plating, missiles, and naval vessels, providing enhanced performance, durability, and protection for military operations.

Gas and Oil

Manufacturers use titanium to fabricate petroleum handling equipment and as a coolant in oil refinery condenser tubes.

Titanium pipe is a great material for deep-sea production risers in petroleum exploration and production because of its lightweight and flexibility. It is also the chosen material for topside water management systems due to its resistance to damage by seawater.

Titanium is the ideal choice in desalination projects worldwide since it exhibits almost no corrosion in saltwater.

Home and Consumer Goods

Titanium alloys are present in a wide variety of consumer products, including toothpaste, paint, some inks, makeup, and some food products. Titanium dioxide, for example, is present in food coloring, paint, and sunscreen.

Sports and Recreation

Sporting goods equipment like racing bicycles feature titanium components.

Chemical Processing

Titanium is useful in chemical processing products such as chemical handling equipment, chemical plant pump units, heat exchanger coils, and heat exchanger linings. It has more lifespan than copper, nickel, stainless steel, and lower initial costs than high nickel alloys, tantalum, and zirconium.

Industrial

Titanium’s applications in industry are expanding quicker than ever before, as more engineers learn how it can increase the lifespan of a wide variety of equipment. The low density of titanium (about 1/2 that of ferrous and nickel-based metals) implies that when apparatus costs are computed per unit area of measure rather than per pound, the material cost gap narrows substantially. Moreover, titanium needs no corrosion allowance when correctly applied; the only factors for choosing wall thickness are pressure and structural considerations for the system.

Power Generation

Titanium thin wall condenser tubing will endure through the lifespan of the condenser and eliminate the need for corrosion permittance in power plants where saline, muddy, or contaminated water is employed as the coolant.

Computer Science

Titanium has the potential to be used as a substrate in hard disc drives in the computer industry. Its non-magnetic qualities eliminate data storage interference. Its capacity to endure heat allows for higher coating temperatures, which in turn improves manufacturing speeds.

Geothermal

Geothermal power generation, in which extremely caustic water discharge from the ground is trapped and used to create energy, has opened up new possibilities. In these applications, titanium’s low lifespan cost saves money when compared to competing materials.

Miscellaneous

Manufacturers also use titanium in a wide variety of miscellaneous products, such as semiconductor and battery wires, paper, cement, agri-food tubing, plastics, gemstones, and titanium jewelry.

Benefits of Titanium

Titanium is a remarkable metal that offers numerous benefits across various industries and applications. Its exceptional combination of strength, lightness, and corrosion resistance makes it highly valuable. Firstly, titanium’s strength-to-weight ratio is unparalleled, as it is about 45% lighter than steel while maintaining similar strength levels. This characteristic makes it a popular choice in aerospace and automotive industries, where weight reduction is critical for fuel efficiency and performance. Secondly, titanium is highly corrosion resistant, even in aggressive environments, due to its ability to form a protective oxide layer. This property makes it ideal for applications in marine environments, chemical processing, and medical implants, where long-term durability is essential. Additionally, titanium is biocompatible and non-toxic, allowing it to be used in various medical devices and implants without causing adverse reactions within the human body. Furthermore, titanium is highly resistant to extreme temperatures, retaining its mechanical properties even in high heat or cryogenic conditions. This quality makes it invaluable in industries such as nuclear power, aerospace, and military equipment. Lastly, titanium’s exceptional resistance to fatigue and wear, coupled with its low thermal expansion coefficient, make it suitable for demanding applications like turbine blades, heat exchangers, and prosthetic joints. Overall, titanium’s unique combination of strength, lightness, corrosion resistance, biocompatibility, temperature resistance, and durability make it a highly versatile and sought-after material with a wide range of benefits in various industries.

Titanium Grade 5

Titanium has different grades in which it is available commercially. One of the most important grades of Titanium is Titanium Grade 5 or Ti 6Al-4V. It is the most extensively utilized of all titanium alloys and is known as the “workhorse” of titanium alloys. It accounts for half of all titanium consumption on the planet.

Its usefulness is based on its numerous advantages. Heat treatment can be used to improve the strength of Ti 6Al-4V. It may be utilized in welded construction at temperatures up to 600 degrees Fahrenheit (315.56 degrees Celsius). This alloy’s excellent stability at a low weight, practical formability, and high corrosion resistance make it a good choice.

Let us discuss some of the special aspects of Titanium grade 5 and see why is it so useful:

Ti 6Al-4V in the Aerospace Industry: Titanium plays a critical part in the construction of aircraft worldwide, and that function is growing every year. Moreover, Titanium makes up approximately 40% of the construction of the F-22 Raptor aircraft. Titanium aircraft castings are widely used due to their outstanding mechanical qualities, including excellent corrosion resistance, strength-to-weight ratio, and fatigue strength. Manufacturing aircraft titanium components and systems, on the other hand, may be a time-consuming and careful procedure.

Ti 6Al-4V in the Medical Industry: One of the primary applications of grade 5 titanium is its use in dental implants due to its high fracture resistance. Titanium’s capability to connect with the bone and live tissue makes it an interesting material for orthopedic implants, i.e., knee and hip replacements. It’s also suitable for a variety of other medical tools due to its strength and higher corrosion resistance.

Ti 6Al-4V in Jewelry Making: Nowadays, titanium grade 5 or aerospace titanium is extensively used in jewelry making because of its durability and versatility.

Titanium’s High Strength to Weight Ratio

Titanium is one of those metals with a very high strength-to-weight ratio compared to other metals. It is a very light metal, but it possesses extremely high strength. In fact, having a strength-to-weight ratio of 45%, Titanium has the highest one of all the available metals. So, due to this property:

- Titanium alloys are frequently utilized in robust, lightweight goods like tennis rackets and bicycles.

- Due to its resistance to saltwater, it is frequently utilized in ship hulls and propeller shafts.

- In terms of metal plating, Titanium may benefit from electroplating services, with platinum, for example, being added to improve its look.

Titanium’s Hypoallergenic Properties

- Titanium is a completely hypoallergenic metal, which is as light as aluminum, but this particular quality makes it a perfect material for making jewelry.

- It does not tarnish or need to be polished, so titanium frames are hypoallergenic, meaning that they will not cause any allergic reaction to the skin.

- Its hypoallergenic property makes it the most suitable material for people with hypersensitive skin.

Titanium as a Ring Material

- Having the highest strength to weight ratio of all the metals

- Having high corrosion resistance

- Being the most biocompatible metal

- Being the most hypoallergenic metal

It can be said that it is the perfect material to be used as a ring material.

Things to Consider Regarding Titanium

If you are interested in purchasing titanium or titanium products, you need to work with a reputable titanium supplier or manufacturer. Working with just any supplier is quite risky, as titanium of an inferior quality can be, at best, detrimental to your application and, at worst, deadly.

Before deep-diving into your search, we recommend you take some time to compose a list of your application specifications and requirements. Think about things like your request volume, your industry standards requirements (military, medical, food and beverage, etc.), your budget, your timeline, your delivery preferences, and your post-delivery support preferences (set-up assistance, parts replacement services, etc.)

Once you’ve written down all of those considerations, you can get started on finding your manufacturer. To help you on your way, we’ve compiled a list of some of the top titanium manufacturers and suppliers in the business. You’ll find their information sandwiched in between these paragraphs. As you browse, frequently consult your specifications list. Pick out three or four that you believe might serve you the best, then reach out to each of them to talk. Once again using your specifications list as guidance, discuss your application at length with each of them. Once you have done that, compare and contrast their answers, and pick the right one for you.

Titanium Overseas Market

Today, a number of different countries produce titanium. The most recent information lists the top six titanium producing countries as (from first to last): China, Japan, Russia, Kazakhstan, the United States, Ukraine, and India.

Despite the fact that China produces the most titanium sponge, it does not have the best market for it, and its exports have declined. At the same time, over the last few years, many major companies around the world have lowered their titanium prices. With the global titanium market like this, where does this leave the American market? The American titanium market is actually in a great place. This is due in part to the highly competitive aerospace market, which features giants like Boeing. To meet this demand, American suppliers have been producing and selling more and more titanium over the last decade. So, you have plenty of high quality options from which to choose, and excellent prices to go along with them. In this environment, you can’t go wrong by shopping American.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services