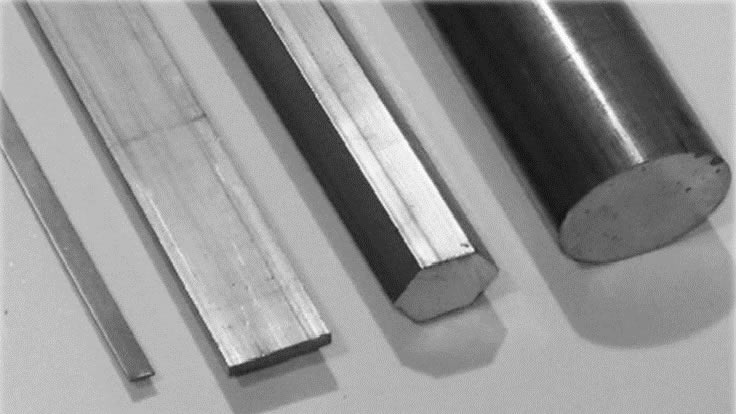

Titanium is an extremely versatile metal with strength that is comparable to steel without the weight of steel. It can be shaped, formed, configured, and alloyed using multiple fabrication methods while retaining its initial properties. Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Buy Titanium Suppliers

Buy Titanium

As useful as titanium is, it requires a great deal of processing to extract it from the ores where it is found. Once it is formed into billets, rods, or sheets, titanium can be worked and shaped; this requires much effort and is expensive due to its hardness.

What is Titanium?

Titanium makes up 0.57% of the earth’s crust, making it the ninth most prevalent metal on the planet. It was discovered in the 18th Century by two European mineralogists, one of whom named it after the Greek god Titan. Titanium is extracted or processed from Rutile, Ilmenite, and Sphene.

The mining of titanium involves an open pit process where soil is dug out and sent to a factory to remove the ore; the process involves a suction bucket on a floating dredge. The mineral rich soil is passed through a screen or trammel that filters out any unwanted elements.

The process for transforming titanium into a usable metal is called the Kroll Process; it involves six steps and is named after William J Kroll, who perfected the process in 1940. Since the development of the process, engineers and researchers have worked to perfect the method to make it easier and quicker to extract the metal.

The Kroll Process

The mining of titanium is similar to the methods used to mine other minerals, and it can use the same type of equipment. Once the ore is screened and filtered, the similarities to other methods of extraction end. Removing titanium from the filtered material involves six chemical processing steps that require various heating and mixing procedures.

The first step is for the titanium oxide ore, collected in the screening, to be combined with chlorine to form titanium chloride. This is unlike the processing of other metals since their oxides do not have to be turned into a chloride. The blending of the oxide and chloride is time consuming and expensive.

The next step is to reduce the titanium chloride using magnesium as a reducing agent. This part of the extraction takes place in a steel reactor that is heated to 1200° C or 2192° F. For this part to be successful, the reactor has to be completely sealed to avoid the titanium being exposed to oxygen and becoming brittle.

The titanium remains in the furnace until it hardens and solidifies into an ingot; this can weigh from one to six tons. Unlike other metals, such as iron or steel, titanium can only be processed in large batches. The time required to process titanium is the main reason it is so expensive.

Titanium Alloys

Titanium has exceptional strength and resistance to heat, water, and salt. Its strength and durability make it ideal for a wide variety of industrial applications. Pure titanium is corrosion and rust resistant. When it is alloyed with other metals, the alloy is as strong and resistant as the base metal but takes on more flexibility and plasticity. Though pure titanium is useful, its alloys have a wider array of applications.

There are six grades of pure titanium (1, 2, 3, 4, 7, 11) and four alloys. The four alloys are Ti 6AL-4V, Ti 6AL ELI, Ti 3Al 2.5, and Ti 5Al-2.5Sn and include traces of aluminum, molybdenum, vanadium, niobium, tantalum, zirconium, manganese, iron, chromium, cobalt, nickel, and copper.

Each of the alloys is designed for specific applications that include heat exchangers, surgical implants, and aircraft and aerospace components. Grade 5, alloy Ti 6Al-4V, is the most commonly used and is included in several industrial and manufacturing applications.

Uses for Titanium

Despite its cost, titanium is one of the most valued metals in industrial and manufacturing operations. In the majority of cases, it is alloyed with other metals to take advantage of their properties and characteristics.

Titanium alloyed with aluminum, molybdenum, manganese, and iron is the principal metal in the manufacture of airframes and engines for aircraft because of titanium’s lightweight and ability to withstand extreme temperatures.

In the medical field, titanium is used as joint replacement material, and in dentistry, it is used for dental implants. Though the joints and implants are expensive, they last for the lifetime of the patient.

Since titanium is resistant to the effects of salt water, in the marine industry, it is used for propellers, riggings, and components that are exposed to salt water. When it is coated with platinum, it provides cathodic protection.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services