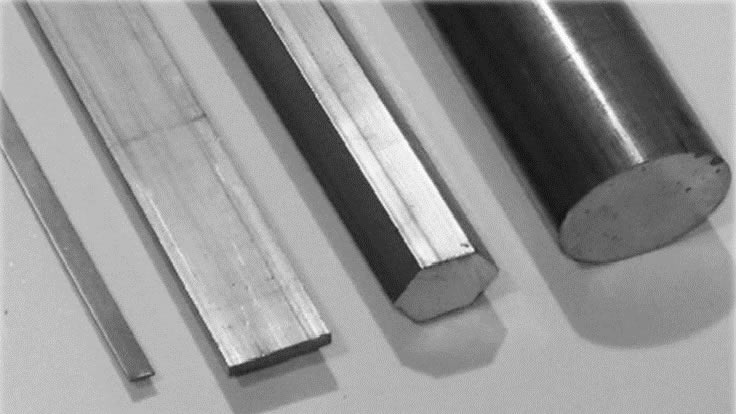

Though most commonly depicted as cylindrical objects, rounded edges are only one of many available options for these rods. Square, hexagonal and flat rods are commonly stocked with custom rod shapes also readily available. Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Titanium Rod Suppliers

Common processes used to create titanium rods include hot forging, hot rolling, polishing, machining, extrusion, welding, casting and spinning. These techniques may also be implemented in the manufacture of specific titanium parts. These shapes may be used as rods or bars, for example in concrete reinforcement or structuring, but are more often melted down or reworked by manufacturers who buy titanium in stock form to create parts for such broad industries as machine building, aerospace, aircraft, shipping, transit, automotive, sport, medical and power generation. Titanium metal and titanium alloys are lauded for their low density, high strength and superior corrosion resistance.

These qualities render titanium 45% lighter than steel of comparable strength and twice as strong as aluminum, copper or brass with only a 60% increase in volume. Resistance to acid, stress, oxygen, salt and microbiological corrosion make titanium the logical and most effective choice for underwater applications, as well as medical implants and prosthetics as it eliminates concern for allergic reactions to the material. Rods allow for easy transportation and use as volume is straightforwardly regulated and pre-forms make shipping and manufacturing processes much more predictable. In some instances, plants will also custom process rods and deliver the final product to consumers.

Although titanium is the ninth most abundant element, making up 0.57% of the Earth's crust, it does not occur in pure form and is instead found in ores, or mineral deposits, such as Rutile, Ilmenite and Sphene, from which it must be extracted. The most common technique for extraction is the Kroll method. This involves forming titanium tetrachloride through fractional distillation. The substance is then reduced to useable metallic titanium using magnesium. The resulting highly porous yield is referred to as a sponge. Rods are formed when this sponge, or bulk, is melted or pressed into specific shapes and sizes.

Manufacturing techniques can be used individually or in conjunction with other techniques to form these stock and custom shapes. Rods are produced using either raw materials provided by the customer or using the resources available in a mill. Some mills will not manufacture rods from outside titanium sources without grade certification and mechanical property testing to ensure that they are outfitted with the proper equipment. Grade of material is a significant consideration as processing high purity titanium is extremely energy intensive. While titanium grades are of utmost importance, further property considerations include rod length and diameter which can vary considerably. Rod diameters, for example, range from ½ inch cross-sections to as large as 13 ¼ inch cross-sections.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services