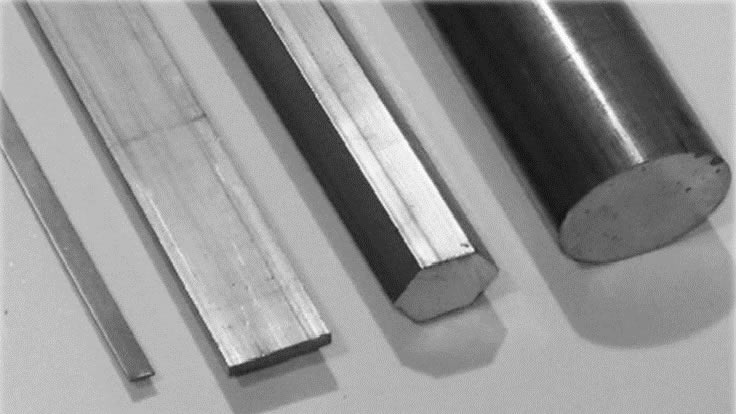

As titanium is a difficult substance to process, manufacturers who work with titanium typically begin their fabrication processes with either titanium sheeting or, for larger quantities, titanium plates which are already prepared for secondary fabrication. Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Titanium Sheet Suppliers

Titanium sheets and plates are made from ore that has already been reduced from its natural mineral depository form. Since titanium does not occur in its pure form in nature, the primary fabrication process is costly and difficult. First, mineral deposits containing titanium - usually ilmenite - must be refined into titanium tetrachloride and then reduced with magnesium in order to be cast into a shape. What usually forms through this is a highly porous bulk, or what is also called "sponge", which is then melted into titanium sheet or plate and is ready for secondary fabrication.

Titanium offers superior strength, rigidity, and lightness compared to other metals and due to these properties is a popular substance choice despite the drawbacks of its extraction process. Industries such as marine, aerospace, automotive, medical and chemical, military and general manufacturing all employ various titanium alloys.

Comparable to steel in strength, titanium is half of steel's density and has excellent corrosion resistance to acid, oxygen, chloride and salt corrosion without the need for galvanization or coating. Because of these properties, titanium offers what is ultimately a cost-effective solution for many uses. It may consist of an initial costly output, but over time due to its durability, strength and resistance to wear, titanium will prove worth the cost. In its various forms of bars, pipes, wire and rods, titanium holds the same amount of strength as copper, steel, brass or aluminum with only half the material volume. Once processed into an ore, titanium is relatively easy to fabricate and extremely useful, which is why many industries choose titanium even at a higher cost, continually researching new possible uses for titanium.

Aquarium, naval and other saltwater industries often use titanium for underwater parts due to its resistance to erosion, stress, microbiological corrosion and pitting. Because it is such a lightweight, high strength material, titanium is used in the automotive industry for valve springs, rocker arms, connecting rods, exhaust systems, drive shafts, steering gear, etc. Other uses for titanium include semiconductor and battery wires, chemical and petroleum handling, agri-food, orthopedics and sporting goods equipment.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services