Known for low density, high strength, corrosion resistance and conductive properties, titanium metal and titanium alloys are up to 45% lighter than steel of comparable strength and twice as strong as aluminum, copper or brass. These benefits are weighed against the cost and difficulty of acquiring and processing this extremely hard substance. Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Titanium Foil Suppliers

The forming of foils, however, is a pre-process that adds ductility to the long list of desirable attributes of the materials and renders titanium easily fabricated. This allows the use of titanium foil in such diverse fields as machine building, aerospace, aircraft, shipping, transit, automotive, sport, medical and power generation.

Foil is used both in the creation of final products as well as in finishing as it is easily molded and adheres to pre-existing forms for added protection, strength and resistance to corrosive materials and environmental wear. Generally available in rolled coils, many manufacturers prefer to buy titanium in this stock form as it is regulated and allows for predictable shipping and processing requirements. Common processes used to create titanium foils include continuous cast stripping, rolling and pressing of cast ingots.

The production of titanium foil necessitates the extraction of titanium from mineral deposits, most often utilizing the Kroll Method. This involves forming titanium tetrachloride through fractional distillation. The substance is then reduced to useable metallic titanium using magnesium. The resulting highly porous yield is referred to as a sponge. Foils are formed when this sponge, or bulk, is melted and then pressed, rolled and cut into predetermined or customized titanium sheets which are sold by the square inch or square foot. Used in such varied applications as capacitor and converter foils, camera shutters, and wind screens, foils offer a wide range of thickness.

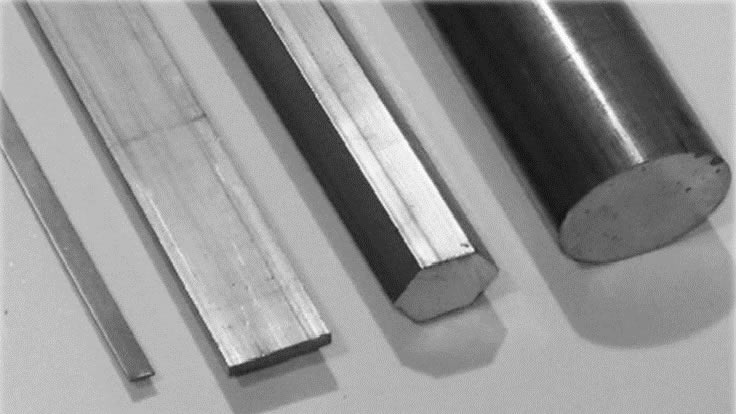

Titanium can be pressed as thin as 0.001". Thicker foils can be up to 0.009" thick, but thicker qualifies as a sheet or titanium plate rather than a foil. Titanium foils are produced using either raw materials provided by the customer or using the mills own resources. Some mills will not manufacture foils from outside titanium sources without grade certification and mechanical property testing to ensure that they are outfitted with the proper equipment. Titanium grade is a significant consideration for manufacturers as processing high purity titanium is extremely energy intensive and ductility varies among the many grades.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services