A titanium bar is a metal bar made specifically from titanium ore. Titanium is an extremely light, elegant, and durable metal commonly used by the industrial sector to create long-lasting, sturdy items. Outstanding corrosion resistance and high strength-to-weight ratio make titanium metal a common choice for building material. Read More…

Banner Service Corp., serving the precision machining industry since 1961, is a premier provider of cold finished bar solutions, offering titanium & exotic alloys for a variety of applications, including medical grade titanium bar products. Extensive inventory and unmatched precision processing capacity & capabilities for ground bars & tubing, and even machined parts, with very short lead times.

Future Metals’ focus is providing aircraft-grade titanium and other metal products to the aerospace industry. We offer titanium tubing, titanium sheet and titanium bar. We also distribute tubing, stringers & extrusions, sheet and bars in aluminum, alloys, high-temperature metals and stainless steel.

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Online Metal Supply is your surplus metal warehouse offering guaranteed low prices for round titanium rods in different diameters & lengths and titanium sheet & plate in various dimensions. Plus, aluminum, brass, bronze, copper, magnesium, laminates, plastics, specialty alloys, steel and stainless steel too.

As an international producer of medical-grade products using our leading precision medical titanium wire, Fort Wayne Metals is a leader in medical wire. Since 1946, we have offered titanium and titanium alloys, round wire, flat wire and cables. Our medical wire ranges in diameter from .0005 - .250 inches.

More Titanium Bar Suppliers

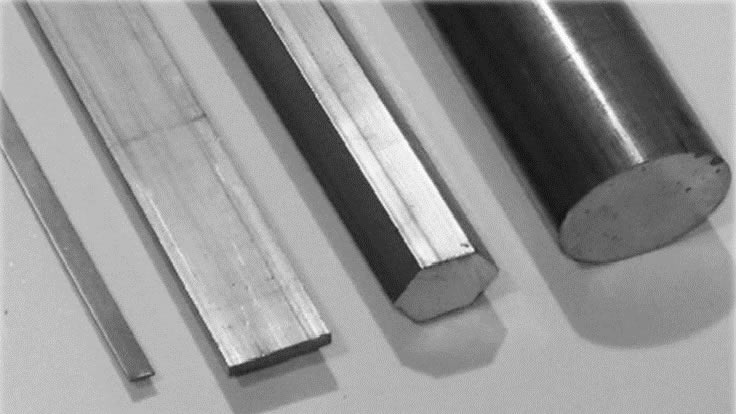

Although titanium is a component of other elements, it does not naturally occur in its pure form. Pure titanium must be removed from ores or mineral deposits. The Kroll procedure and the Hunter method are popular techniques for removing titanium. Common titanium products include blocks, plate forms, and round bars. Although incredibly popular, the production of titanium round bars requires an automated procedure. Titanium bars are available in over forty distinct grades, the most popular grades being 5 and 2. Titanium bars are available in up to 14-inch diameters.

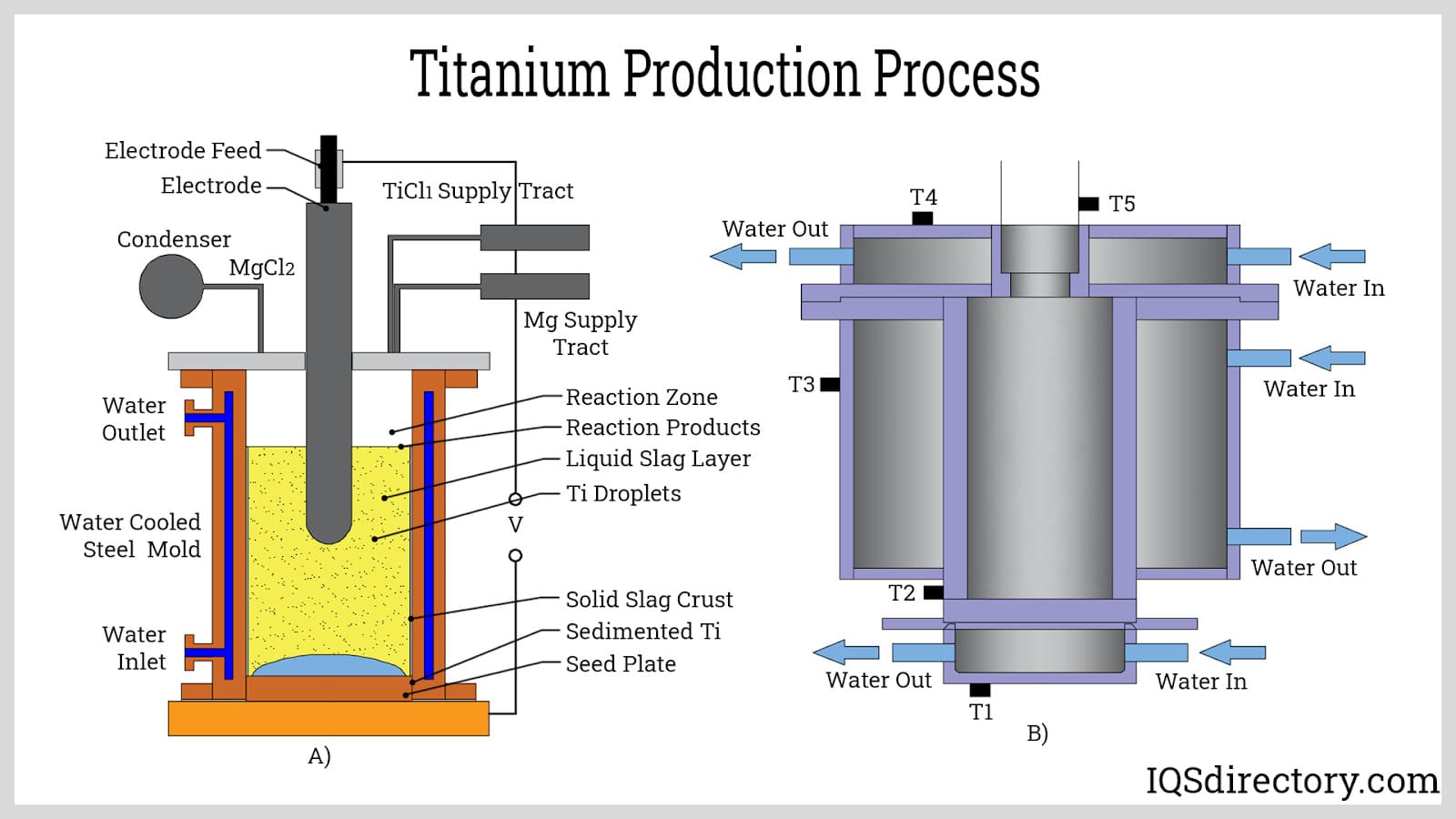

How Titanium Bars are made

Titanium is usually produced from rutile ores, ilmenite ores, and occasionally sphene ores. The Kroll method is used for the entire titanium manufacturing process. First, magnesium is used to heat titanium (IV) chloride. This procedure causes titanium dioxide to combine with chlorine to create titanium tetrachloride. Then, when the tetrachloride reacts with magnesium, any remaining chlorine is removed. When the chlorine is stripped away, A pure metal called a sponge is created. This is the "titanium" that is ready to be formed and shaped for various purposes.

Titanium bars are created through the process of forming and shaping. The sponge may be melted with alloying components like aluminum or vanadium and then formed into bar shapes during the forging process. It can also be processed further to create sheets, which can then be cut into strips and used to create pipes, tubes, or bars. The final shape and form of the titanium bar will depend on its intended use.

Advantages of Using Titanium Bars

- Companies that produce titanium extol the robust, glossy qualities of titanium in its unalloyed form, enabling customers to find goods with a premium appearance.

- Titanium rods are durable; customers can have their needs met and expenses reduced due to the long-lasting features of titanium rods.

- Titanium is useful for medical implants through osseointegration (where metal binds to human bone). The immune system detects the titanium rod and doesn't fight it since it believes it to be a pathogen. Titanium has good biocompatibility. The human body tolerates large amounts of titanium because it forms a thin oxide layer.

- Titanium is tremendously strong and resilient, making it a fantastic substitute for gold jewelry. Due to its hypoallergenic qualities, titanium jewelry is an attractive alternative for the health-conscious. Titanium can maintain the nervous and muscular systems' electrical waves. Anyone trying to balance electromagnetic energy in the body to get rid of a stiff neck, migraines, or dizziness can consider titanium jewelry.

Applications of Titanium Bars

- Titanium is used for countless industrial purposes and parts. The manufacturing industry uses titanium in petroleum extraction, power plants, and extraction processing facilities.

- Major consumers of titanium bars include technology, armor, and construction businesses.

- The aircraft sector frequently uses titanium bars and sheets. Titanium bars are used in aircraft structures, aviation engines, and propellers. The aerospace industry is one of the largest consumers of titanium.

- Laptop manufacturers use titanium because of its sleek, contemporary, and industrial appearance.

- The dentistry industry uses titanium bars, wires, and plates to make dental implants because it’s a non-allergenic metal.

Choosing the Right Titanium Bar Manufacturer

To make sure you have the most positive outcome when purchasing titanium bars from a titanium bar manufacturer, it is important to compare at least 5 manufacturers using our titanium bar directory. Each titanium bar manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each titanium bar business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple titanium bar businesses with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services