Rickard Specialty Metals & Engineering

Rickard Specialty Metals & EngineeringRequest A Quote

Ontario, CA | 800-966-4922https://www.rickardmetals.com/

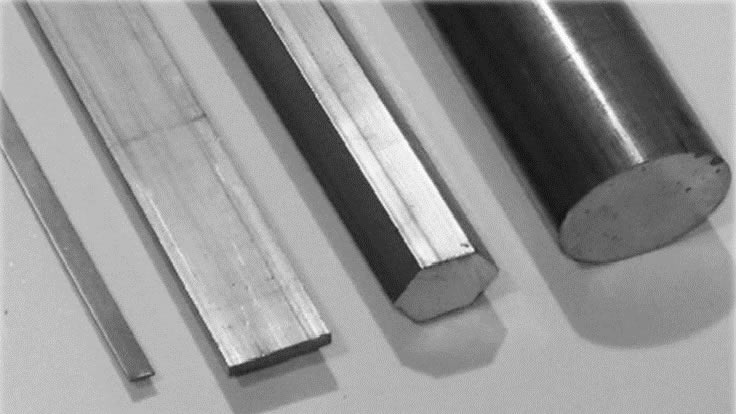

We are Rickard Specialty Metals & Engineering, a seasoned industry leader with over 25 years of unparalleled expertise in providing top-tier titanium products and comprehensive engineering solutions. Our commitment to excellence and innovation has solidified our position as a go-to partner for businesses operating within the aerospace, military, and other rigorous sectors. At Rickard Metals, our core specialization revolves around titanium forgings, a critical component of highly technical projects that demand nothing short of perfection. With a proven track record in delivering impeccable results, we have played an integral role in shaping the success of numerous complex endeavors. Our involvement in these cutting-edge industries underscores our unwavering dedication to precision and quality. We pride ourselves on our diverse inventory, which encompasses a wide range of titanium forms, including billets and bars. This comprehensive selection ensures that we can cater to a broad spectrum of project requirements, offering flexibility and customization that meet the unique needs of each client. What truly sets us apart is our ability to tailor titanium products to exacting specifications, providing you with a seamless solution that aligns perfectly with your project's vision. The heart of our service lies in our state-of-the-art engineering capabilities. Our skilled team of experts possesses an unmatched wealth of knowledge and experience, enabling us to not only supply exceptional titanium products but also offer invaluable consultation and support throughout the entire project lifecycle. From initial design and material selection to precision cutting and meticulous quality control, we are with you every step of the way, ensuring your project's success. As a forward-thinking company, we continually invest in the latest technologies and methodologies to maintain our competitive edge. This dedication to innovation empowers us to tackle even the most intricate challenges head-on, pushing the boundaries of what is possible in titanium forging and engineering. With Rickard Metals as your partner, you gain access to a dynamic synergy of expertise, cutting-edge technology, and a relentless pursuit of excellence. In a world where precision and reliability are paramount, Rickard Specialty Metals & Engineering stands as your unwavering ally. Our titanium products and service capabilities are a testament to our unwavering commitment to quality, innovation, and client satisfaction. Join us on the forefront of progress, and together, we will forge a future defined by excellence.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services