Rex Metals

Rex MetalsRequest A Quote

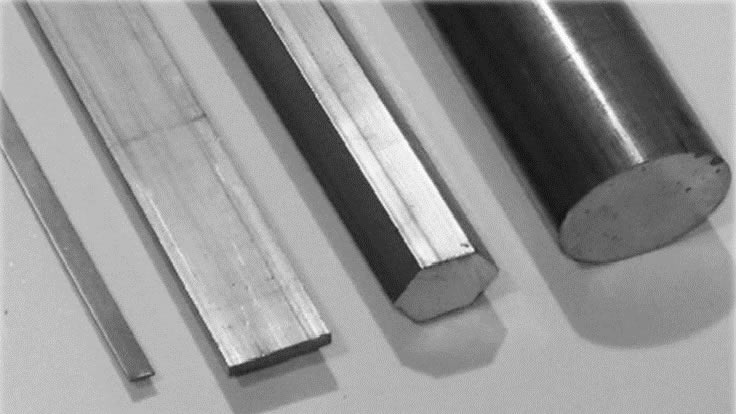

Loma Linda, CAAt Rex Metals, we pride ourselves on being a leading force in the world of advanced metal solutions, with a distinct focus on titanium products that redefine innovation and excellence. Our unwavering commitment to quality and cutting-edge technology has established us as a premier partner for industries seeking top-tier titanium solutions. With a passionate team of experts at the forefront of metallurgy and materials science, we harness the power of titanium to forge a wide range of products and services that cater to the diverse needs of our valued clients. Our extensive portfolio includes but is not limited to titanium alloys, sheets, plates, bars, rods, tubes, and customized components, each meticulously crafted to meet the most stringent specifications and performance demands. Rex Metals stands as a beacon of excellence when it comes to the comprehensive capabilities we offer. Our state-of-the-art manufacturing facilities employ advanced processes such as precision machining, additive manufacturing, and metal injection molding, ensuring that every titanium product that leaves our premises is imbued with unparalleled precision, durability, and reliability. We understand that every client is unique, and as such, we take great pride in our ability to provide tailored solutions that address specific requirements. Our team of dedicated engineers and metallurgical experts collaborate closely with clients to design and produce bespoke titanium components that seamlessly integrate into their applications, be it aerospace, medical devices, automotive, marine, or industrial machinery. At Rex Metals, innovation is embedded in our DNA. We relentlessly pursue research and development initiatives to push the boundaries of what titanium can achieve. This ethos not only enables us to offer cutting-edge titanium products but also positions us as a partner for clients seeking to stay at the forefront of their respective industries. As a company that values integrity and transparency, our client relationships extend beyond transactions. We foster long-term partnerships built on trust, communication, and mutual success. Whether you require a standard titanium product or a groundbreaking innovation tailored to your specific needs, Rex Metals is your unwavering partner throughout every step of the journey. In summary, Rex Metals is your definitive destination for titanium solutions that encompass a rich spectrum of products and services. With a passionate team, cutting-edge technology, and a commitment to quality, we stand poised to lead industries into a future where titanium's exceptional properties revolutionize possibilities.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services