Plymouth Tube Company

Plymouth Tube CompanyRequest A Quote

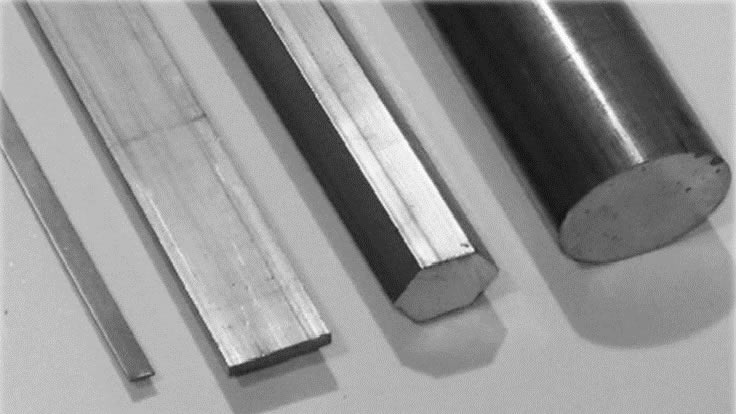

Warrenville, IL | 800-323-9506We are Plymouth Tube Company, a leading manufacturer and supplier of titanium products, renowned for our exceptional quality and comprehensive service capabilities. With a rich heritage dating back over a century, we have established ourselves as a trusted name in the industry, catering to diverse market segments across the globe. As our primary focus, we specialize in the production and supply of titanium products. Titanium is a versatile and highly sought-after material known for its exceptional strength, corrosion resistance, and lightweight properties. We source titanium from reliable and reputable suppliers, ensuring the highest quality standards are met. By maintaining strong relationships with our suppliers, we guarantee a steady supply of premium-grade titanium materials to meet the ever-evolving needs of our customers. We offer an extensive range of titanium products, including tubes, pipes, bars, sheets, plates, and custom-engineered components. These products find applications in various industries such as aerospace, defense, automotive, oil and gas, medical, and many others. Whether it's for critical aircraft structures, surgical implants, high-performance sports equipment, or industrial machinery, our titanium products deliver exceptional performance and reliability. One of our key strengths lies in our state-of-the-art manufacturing facilities and advanced production capabilities. Equipped with cutting-edge machinery, stringent quality control measures, and a highly skilled workforce, we ensure the precision manufacturing of titanium products to meet the most demanding specifications. Our expertise extends to intricate designs, complex geometries, and tight tolerances, making us a preferred partner for projects with challenging requirements. In addition to our strong manufacturing capabilities, we place great emphasis on innovation and continuous improvement. We invest in research and development to stay at the forefront of technological advancements in titanium processing and applications. By leveraging our technical expertise and industry knowledge, we offer value-added services such as material optimization, cost reduction initiatives, and design enhancements, helping customers achieve their goals efficiently and effectively. With a strong focus on customer satisfaction, product quality, and technical expertise, we stand as a trusted partner for all titanium product needs. Our commitment to excellence, continuous innovation, and comprehensive service capabilities make us the go-to choice for customers seeking reliable and high-performance titanium solutions.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services